Adhesive Backed Magnets are just what the name implies, neodymium magnets with adhesive on one side that matches their size. These magnets come with tape on one side, which is known for its strong adhesion and durability.

Magnets with adhesive backing are a popular and convenient choice for a wide range of applications, providing an easy way to mount magnets to a variety of surfaces without drilling or other mechanical fasteners. Due to their ease of use and versatility, adhesive-backed magnets are widely adopted in a variety of applications. Here are some common applications for adhesive-backed magnets:

- Home use: Adhesive-backed magnets can be used to fix and display household items. For example, you can hang photos, paintings, calendars, notes, etc. on refrigerators, whiteboards or walls, and fix curtains, fabrics, etc.

- Office Use: Adhesive-backed magnets are suitable for office environments. You can use them to fix files, memos, notes, charts, and other important documents to magnetic surfaces such as steel filing cabinets, whiteboards, magnetic walls, etc.

- Advertising and Display: Adhesive-backed magnets are very common in the advertising and display industries. They can be used to make removable signs, posters, menus, display boards, etc., which are convenient for display in different places.

- Making magnetic tools and components: Adhesive-backed magnets can be used to make magnetic tools and components, such as magnetic knife holders, magnetic tool trays, magnetic pin holders, etc.

- Education and entertainment: In the field of education and entertainment, adhesive-backed magnets can be used to make magnetic puzzles, teaching materials, creative games, etc.

These are just some common application examples. In fact, adhesive-backed ndfeb magnets have a wide range of uses. When using them, there are some important considerations to ensure the performance and safety of the magnets:

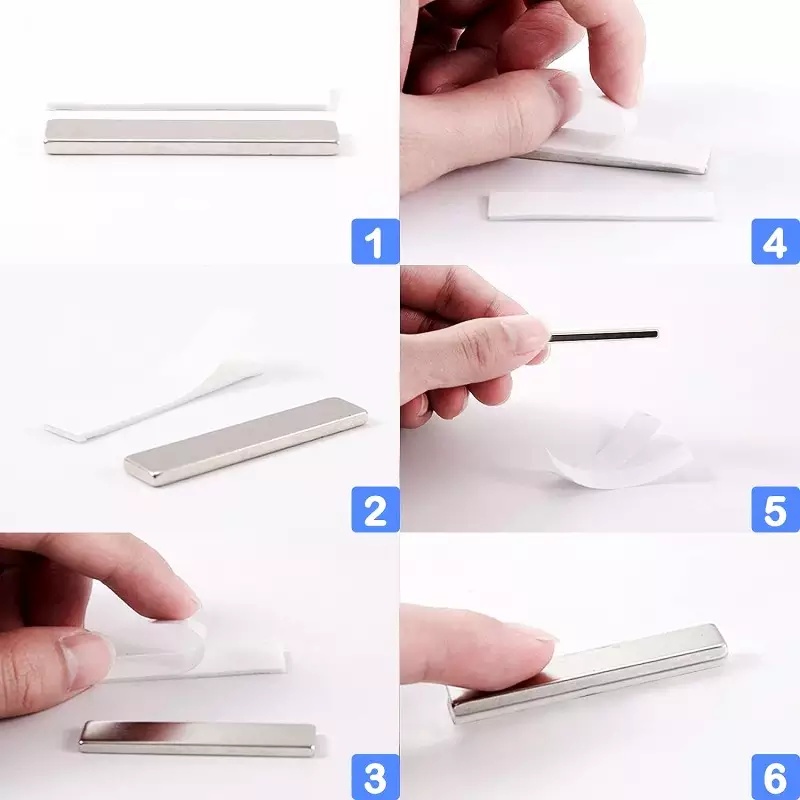

- Surface cleaning: Before pasting the magnet, make sure the surface to be pasted is clean, dry and free of oil. You can wipe it with a clean cloth or wet paper towel, and then wipe it with a dry cloth to avoid debris affecting the pasting effect.

- Avoid moisture and humidity: The stickiness and magnetic force of adhesive-backed magnets may be affected in a humid environment, and they are prone to lose stickiness or reduce adsorption capacity, so it is best to use them in a dry environment.

- Avoid excessive pulling: Although the adhesive-backed magnets have strong adhesion, excessive pulling or rubbing may cause the adhesive layer to fall off or the magnet to be damaged. Avoid strong pulling when using.

- Magnetic force limitation: Adhesive-backed magnets of different sizes and types have different load-bearing capacities. When using, you should choose the appropriate magnet according to actual needs and do not exceed its load-bearing capacity.

- Avoid high or low temperatures: Adhesive-backed magnets may lose their stickiness or magnetic force at extreme temperatures (such as high temperatures over 60°C or low temperatures below -10°C). Avoid exposing them to these extreme temperatures.

- Avoid strong magnetic field interference: If the adhesive-backed magnet is used in a strong magnetic field environment (such as near high-power electrical appliances, magnetic field testing equipment, etc.), it may be interfered with, resulting in weakened magnetic performance.

- Avoid contact with chemicals: Avoid exposing adhesive-backed magnets to strong acids, strong bases, or other corrosive chemicals, which may damage the adhesive layer or affect the magnetic force.

- Gentle removal: If you need to remove the adhesive-backed magnet, be careful not to use too much force. You can first gently heat the adhesive surface (for example, using a hair dryer) to help soften the adhesive surface, making the removal process easier without damaging the surface.

By following these precautions, you can ensure the good performance and long service life of your custom adhesive-backed magnets.