Cooling fans are an indispensable component of modern computers, electronic equipment and automobiles. In order to improve heat dissipation and performance, we are constantly looking for innovation and development. This paper will discuss the important effects of motor and blade materials on the performance of cooling fans.

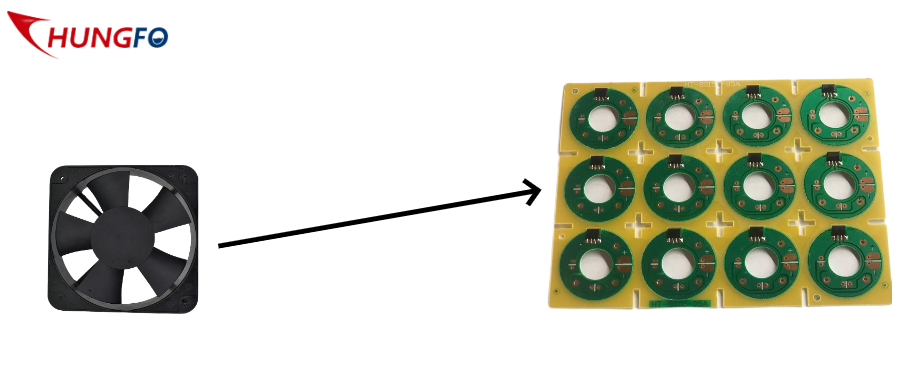

(1)Motor materials

Steel:It has the characteristics of high magnetic conductivity, low loss and easy processing, so that the motor can maintain a high frequency during operation. However, the disadvantage is that the density of steel is large, and it is easy to produce hysteresis loss.

Carbon fiber: It’s suitable for high-speed, high-efficiency motors. Carbon fiber has the advantages of high magnetic conductivity, high strength and light weight, which can improve the efficiency and output power of the motor. The only drawback is the high price.

Copper: It’s an excellent conductive material and is often used to make coils and conductors in electric motors. Copper has a higher electrical conductivity than aluminum. Our model 6A610 DC brush torque motor is a pure copper wire coil, with high electrical and thermal conductivity, can reduce resistance and heat loss. In addition, the DC brush motor consists of a rotor, stator and brush ring assembly, designed as an integral part of the system, which is even more weight and space saving. As a manufacturer, we strongly recommend this DC brush hollow cup motor for beauty products, remote control toys, electric toothbrushes, USB small fans, smart electronics and other devices. Welcome to purchase needs of everyone to come to consult!