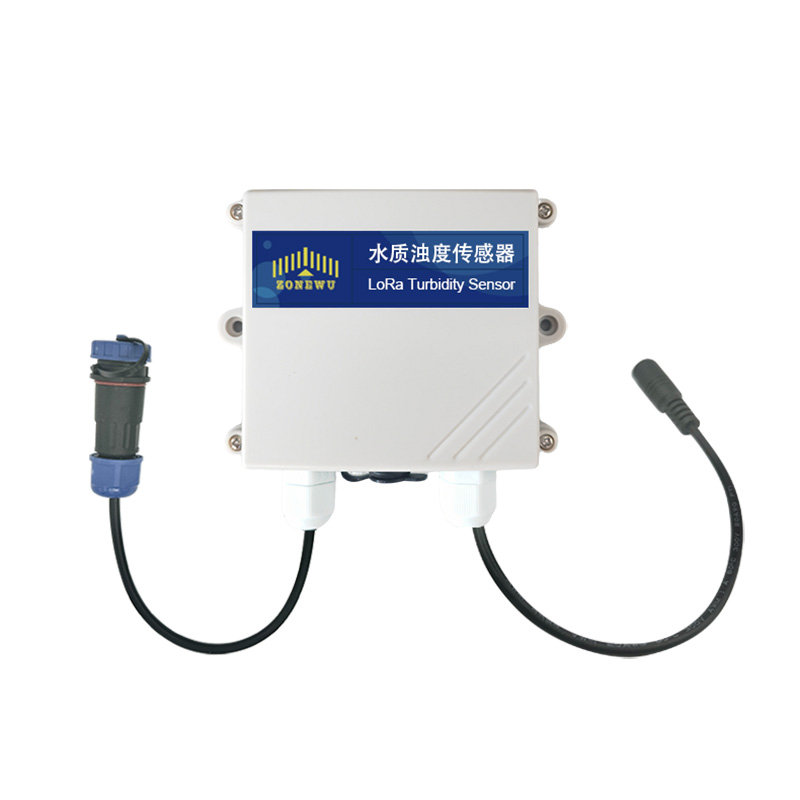

In today's era of increasing environmental awareness, water quality monitoring is essential to ensure ecological balance, human health and the stable operation of industrial production. Among the many water quality monitoring equipment, LoRaWAN water turbidity sensor has gradually become the first choice in various industries with its unique advantages. Today, we will delve into the star product of Xiamen ZhongwuZhilian Technology Co., LTD. --LoRaWAN water turbidity sensor.

Excellent Technical Principle, Accurate Perception Of Turbidity Changes

- LoRaWAN water turbidity sensor uses advanced optical scattering principle to accurately detect the degree of light scattering of suspended particles in the water body, so as to quickly and accurately calculate the turbidity of the water body. When the light hits the suspended particles in the water, these particles will scatter the light, and the sensor converts it into turbidity data by capturing the intensity and Angle of the scattered light, combined with a precision algorithm. This technical principle not only ensures the high accuracy of the measurement, but also effectively avoids the interference of other factors on the measurement results. Whether it is clear drinking water or cloudy industrial wastewater, it can accurately give the turbidity value.

LoRaWAN Technology Enables Long Distance And Low Power Transmission

- This sensor from Xiamen ZhongwuZhilian is equipped with LoRaWAN wireless communication technology, which gives it an unparalleled advantage in data transmission.

- LoRaWAN is a low-power wide-area network protocol with an extremely long transmission distance. In open areas, the data transmission distance can reach several kilometers, easily meeting the monitoring needs of remote areas or large areas of water. It can transmit data stably to the receiving end even in environments where the terrain is complex and the signal is susceptible to interference. At the same time, its low power consumption characteristics greatly extend the battery life of the sensor, reduce the trouble and cost of frequent battery replacement, and provide a strong guarantee for long-term and continuous water quality monitoring.

Ultra-High Sensitivity And Wide Measurement Range For A Variety Of Scenarios

- In terms of sensitivity, this sensor is excellent, can be sensitive to capture the small changes in water turbidity, even the very subtle fluctuations in water quality, but also its "eyes". Its measurement range is also quite broad, from nearly clear water to extremely high turbidity of sewage, can be accurately measured, whether it is used for daily monitoring of drinking water sources, to ensure the safety of drinking water for residents; Whether it is used in sewage treatment plants to monitor the purification effect of sewage, or in aquaculture to ensure the health of aquaculture water bodies, it can be perfectly competent to provide reliable data support for different industries.

Rugged Design, No Fear Of Harsh Environments

- The environment of water quality monitoring is often complex and changeable, and may face harsh conditions such as high temperature, high humidity, strong acid and alkali. LoRaWAN water turbidity sensor adopts special materials and processes, and has excellent protection performance. Its shell is strong and durable, with high waterproof and dustproof grade, which can effectively resist the erosion of the external environment, ensure that it can work stably in various harsh environments, and provide users with continuous and reliable water quality monitoring services.

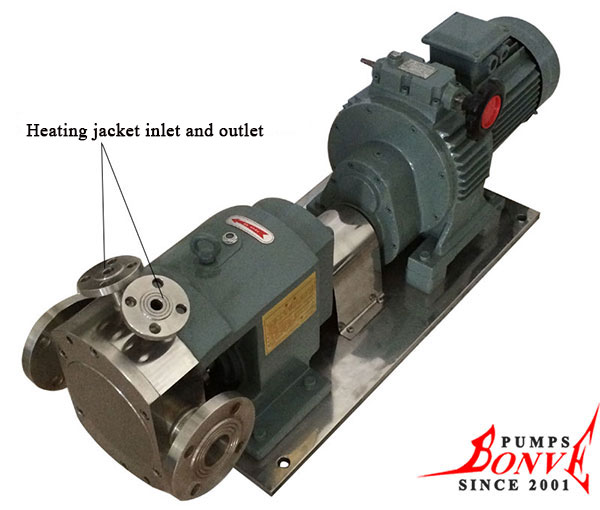

Convenient Installation And Maintenance, Reduce The Cost Of Use

- In practical applications, the ease of sensor installation and maintenance is also an important consideration. The LoRaWAN water turbidity sensor is exquisitely designed, and the installation process is simple and fast. It can be easily installed without professional technicians and complex tools. Moreover, its maintenance cost is low, and only simple cleaning and regular calibration are needed to ensure the normal operation of the sensor, which greatly reduces the user's use cost and time cost.

LoRaWAN Water Turbidity Sensor stands out in the field of water quality monitoring with its precise measurement, efficient data transmission, wide applicability and easy maintenance. If you are looking for a reliable equipment for water quality monitoring, then this LoRaWAN water quality turbidity sensor is definitely worthy of your trust, it will bring a new experience and guarantee for your water quality monitoring work.