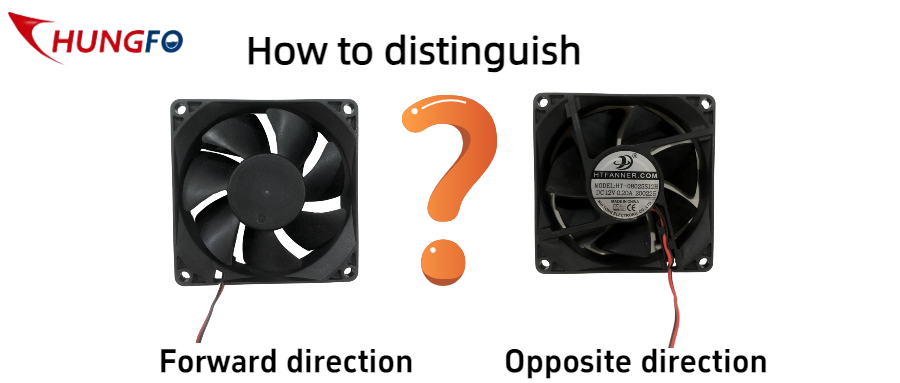

It is very important to understand the positive and negative direction of the DC cooling fan, especially during installation and use. Correctly determining the fan rotation direction can effectively improve the heat dissipation effect of the device. The following are some ways to distinguish the positive and negative direction of the DC cooling fan:

Observe the direction of blade rotation: Generally speaking, from the front of the fan, clockwise rotation is positive, counterclockwise is reverse.

Check the markings on the fan: Many fan housings will have arrow markings indicating the airflow and direction of rotation. The air flow following the direction of the arrow is usually positive.

Airflow test: After power, feel the airflow direction of the front or back of the fan, and the airflow blown out of the front is positive, and the reverse is reverse.

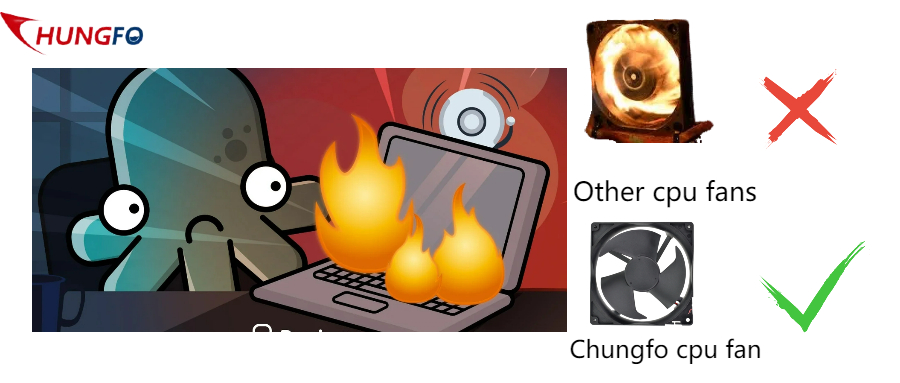

Chungfo is very experienced in the production of 24v DC cooling fans, because we do 24v dc cooling fan Wholesale all year round Whether you are looking for wholesale 24 volt dc cooling fan supplier, or need 12v dc cooling fan Wholesale, understanding how to distinguish the positive and negative of the fan will help you better choose and use the product. We provide all kinds of DC cooling fan wholesale services to meet your different needs.